Why Choose Us?

Experience and Quality

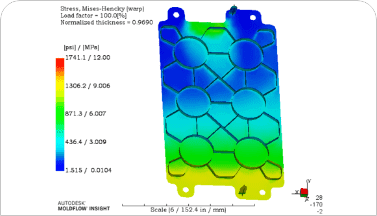

At Bozilla Corporation, our 20+ years of experience in the Plastics Industry gives us an edge when assisting you with injection molded part development. We utilize the latest Autodesk Moldflow finite element analysis software products and geometry techniques to complete your project with the highest quality according to your goals.

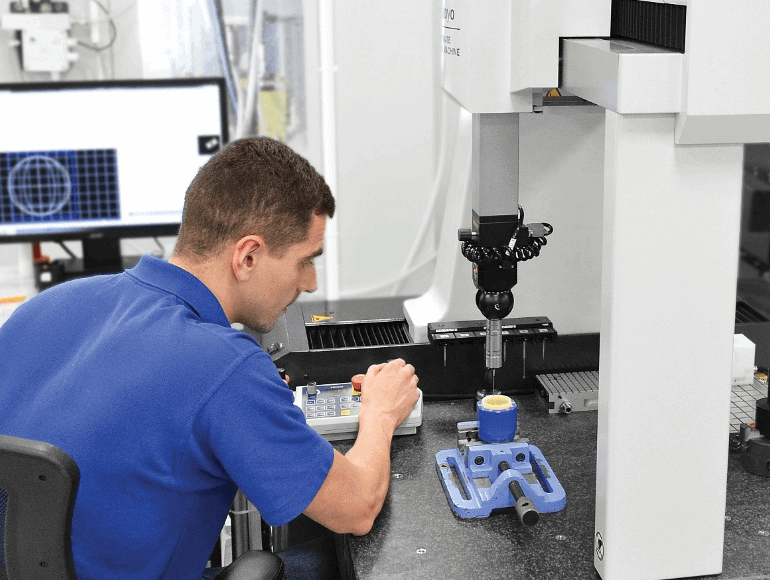

Our injection molding experts will provide consultation to your engineers and processors via scientific workflow using a 3 step procedure.

- Part Validation

- Process Optimization

- Part Quality Assurance

Some of our Advanced Simulation Analyses include:

- Flow analysis

- BEM Cool, FEM Cool analyses

- Warp analysis, Reverse Warp (Windage) analysis

- Gas Assist analysis

- Co-injection analysis

- Autodesk Moldflow MPI/3D, MPI/Fusion Dual-Domain and Midplane technology

We also incorporate both proven field techniques, new technologies and field experience to assist you in generating the best parts in the industry.

Plastics Injection Molding Consulting Services

We use a unique system of analysis, experience with polymers, and other proprietary factors and methods to determine the cause of molding problems.

- Lean your process

- Optimize your injection molded part

- Get solutions for molding issues

- Save money

- Make a good part (no rework)

- Meet your timeline & goals

We Know Plastics Injection Molding

- We use Scientific methods in all of our analyses

- Our Team has over 20 years experience in the injection molding industry

- Meet timing, budget and goals utilizing our methodology

- Make a good part/mold the first time

Our Services

We offer a full suite of Injection Molding Services.

Injection Molding Strategy Consultation

Our consultants utilize their expertise and vast knowledge to guide you through part design, mold design, and process optimization.

Analytical Services

We are Expert Certified and use the latest version of Autodesk Simulation Moldflow Insight for our analyses.

Failure Diagnosis – Product & Process

We use proprietary methods to diagnose failure of your part and find solutions for both product and process- getting you back on track.

Moldflow Mentoring Service

▶ Receive Expert Level of Coaching for Your projects

▶ Provides Remote mentoring for the Autodesk Moldflow software

▶ Available to All Skill Levels

What is a 30 minute plastics injection molding strategy consultation?

Our Expertise =

Your Project Success

Discover how our injection molding experts can assist you in successfully meeting your goals.

- An opportunity to discuss your injection molding needs and goals.

- Ask part, process, project, design questions.

- Find solutions to problems and challenges.

- We will set up a phone call with professionals with 20+ years of Injection Molding experience.

30 minute

injection molding strategy consultation

Bozilla Corporation has Degreed Plastics Engineers and is Expert(Gold)Certified with the Autodesk Moldflow software. We are also a training partner with Autodesk.

Testimonials

Our Client Testimonials

Inteva Products

I just wanted to say “Thank you” for going out of your way and using your expertise. This time I know things have been evaluated correctly.

Parkway Products

The Moldflow was extremely informative and the presentation was best in class.

Yamaha

Thanks for your dedication, knowledge and expertise in assisting me with a successful design.

Completed Sun Roof project:

Historically, Yamaha’s Sun Roofs have been gas assisted for strength and press tonnage requirements. One of the potential major drawbacks of using the gas assist process are the inevitable non-unifo

Toter Incorporated

“The design showed the broken lids were in spec. Based on your analysis, we changed the lid molding process and the material grade we use. Additionally, to make sure all this stays in check, since

“Just a short note to say thanks for your work on our molded bezel project.

This was the first Moldflow that will produce better parts. Particularly your suggestion to modify and taper the thickness at the bottom of th

Our company provides components to the power utility and telecom industries. We have been developing a product that will give us the opportunity to have a presence in the Korean power market. This new product requires a unique

Synventive Simulation Team

Synventive is one of the world’s largest providers of hot runner systems, machine nozzles, temperature controllers and sprue bushings for the injection molding industry. In order to ensure

Get in touch

Ask The Plastics Injection Molding experts!

Contact us for more details and queries.

540-745-4600

info@BozillaCorp.com

Request a Quote

Please complete the FEA Worksheet or Contact us by email or phone for Training Quotes or additional information.