Failure Diagnosis

Our injection molding failure diagnosis procedures can help lean your process and potentially save you money.

We receive frequent inquiries about product or process failure. An unknown variable is not working correctly and a part cannot be made to the desired specifications.

HERE ARE SOME TYPICAL ISSUES:

1) The parts seem fine but are failing at the production location which is causing customer dissatisfaction and additional work/costs for your company

2) Parts are warping out of tolerance

3) Start up time on the same tool vary from machine to machine

4) The process has variation and is producing bad parts

We can help

Bozilla Corporation can provide Failure Diagnosis for both Product and Process. We use both scientific and non-scientific methodologies to arrive at a solution.

Our methodology to determine cause of failure: Scientific Methods

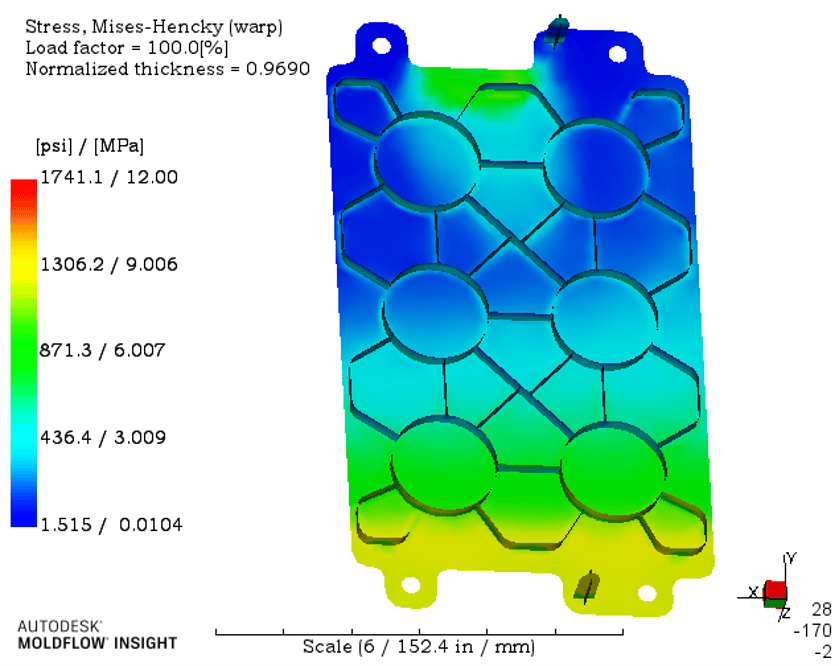

- Autodesk Moldflow Analysis

- Root Cause Analysis

- Our combined Experience with similar issues

- Indepth knowledge of polymers

Get in touch

Ask The Moldflow Experts!

Contact us for more details and queries.

540-745-4600

info@BozillaCorp.com

Request a Quote

Please complete the FEA Worksheet or Contact us by email or phone for Training Quotes or additional information.