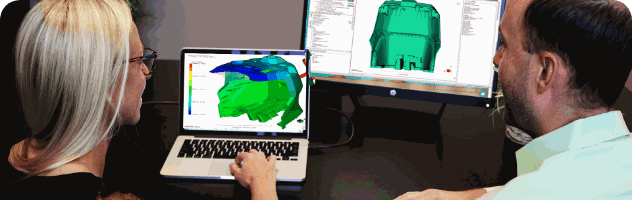

INSIGHT ADVANCED FLOW+COOL+WARP

Course Description

What You Will Learn?

Students learn about the more complex analysis types available in Autodesk Moldflow Insight that were not covered in the Autodesk Moldflow Insight Fundamentals course. Additionally, Students will learn how to analyze how injection molded parts are cooled and how cooling, filling and packing influence the part’s warpage. You will also learn how to optimize the injection mold’s cooling system, and how to reduce warpage.

Learning Details

Family Tools:

Discusses how to analyze family tools including finding processing conditions, adding studies together and balancing the runners

Multiple Gates:

Discuss types of Multiple Gate problems that occur and how to analyze them. Also discusses clamp tonnage and how to work within the limits of the molding machine.

Packing Optimization:

Discusses procedure for reducing variation of volumetric shrinkage on part

Part Insert Overmolding:

Discusses definitions and capabilities with regards to running a flow analysis with part inserts.

Two-Shot Sequential Overmolding:

Discusses capabilities of two-shot sequential overmolding, setting up the analysis, running the analysis and reviewing results

Design of Experiments (DOE) Analysis:

Discusses theory of DOE & how to set up analysis and interpret results

Using Valve Gates:

Discusses valve gate control methods, and how to set up

Core Shift Analysis:

Learn how to prepare for, run and interpret the results of a core shift analysis

Projects:

Practice what you have learned with different models presented with diverse problems.

Database Management:

Discusses how to create personal databases of all types and how to use them

Fiber Flow Analysis:

Learn about a fill and pack analysis for fiber filled materials, Why and when to do a fiber flow analysis

Cooling Overview:

Take an overview of the importance of cooling and review the basic concepts of cooling injection molds

Cooling Results Interpretation:

Review the objectives of a cooling study and how results can be interpreted

Cooling Analysis Modeling Requirements:

Learn about what can be modeled for cooling and how mesh quality influences the analysis

Modeling Cooling Components:

Learn how to model the various features available in a cooling analysis

Cooling Analysis Strategies:

Learn when and how to use the automatic and specified cooing analysis options

Cooling Optimization:

Solve a mold cooling problem by modifying an existing cooling system with your design modifications

Warpage Overview:

An overview of the causes of warpage and shrinkage models used in simulation

Design Influences on Warpage:

Discusses the contributions to warpage with respect to part design, mold design, processing conditions, and materials

Warpage Analysis Process:

Discusses the procedure for running a warpage analysis and how it is related to cooling, filling, and packing

Determine the Magnitude of Warpage:

Discusses the procedure for determining how much the part will warp. It discusses the differences between midplane, Dual Domain and 3D meshes

Determine the Cause of Warpage:

Discusses how to determine if the major cause of warpage is differential cooling, differential shrinkage, orientation effects, or corner effects and how the procedure is dependent on mesh type

Reducing warpage:

Discusses the diagnostic results that can help you understand the causes of warpage and the procedure used to solve warpage problems

Who Should Attend?

- Intermediate Users of Autodesk Moldflow Insight

- Must have attended Autodesk Moldflow Insight-Fundamentals

- 5-day web-training course

What You Will Need

- Training files set up on your computer

- Autodesk Training Manual

- Training Paid in Full prior to start of class

(Bozilla will provide Instructions for the above items prior to training)

Benefits of Web Training

- Train in any convenient location

- No travel or travel expenses

- Autodesk Moldflow curriculum

Live Demo

Option to have Instructor use your “Live” part to demonstrate exercises Students perform during class. (Instructions will be provided)